Introduction to SCADA

In the world of modern industry, efficiency and productivity are paramount. To achieve optimal performance, businesses rely on advanced systems that seamlessly monitor and control their operations. One such groundbreaking technology is SCADA, an acronym for Supervisory Control and Data Acquisition. SCADA is a category of software and hardware solutions that revolutionize industrial control systems, enabling organizations to streamline processes, enhance safety, and maximize productivity. In this article, we will delve deep into the intricacies of SCADA, exploring its components, functionalities, and significant advantages. By the end, you will have a comprehensive understanding of SCADA’s role in shaping the future of industrial automation.

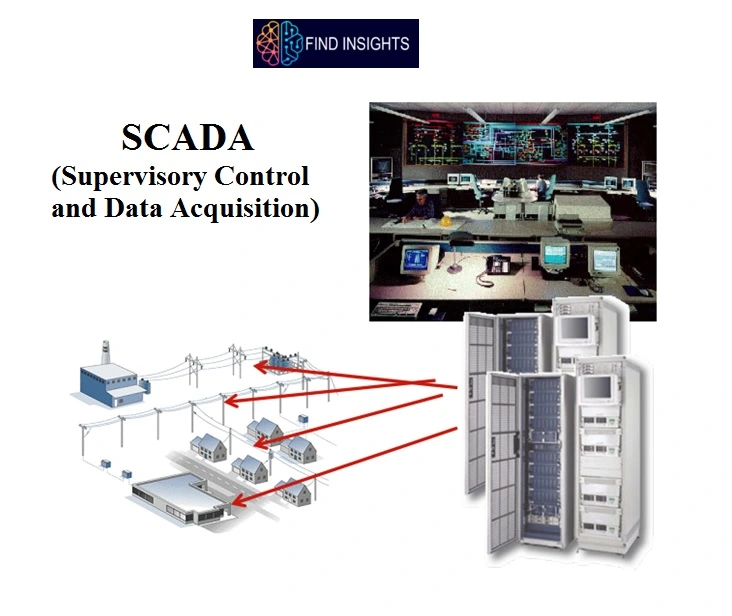

SCADA full form – Supervisory Control and Data Acquisition

The Essence of SCADA

At its core, SCADA empowers industries to monitor and control various processes within their operational infrastructure. It acts as a centralized system that facilitates the gathering, processing, and visualization of real-time data from multiple remote sites. SCADA technology combines the power of computers, software applications, and networked data communications to establish a robust framework for comprehensive monitoring and control. By seamlessly integrating these elements, SCADA enables businesses to make data-driven decisions, optimize efficiency, and ensure operational continuity.

Key Components of SCADA Systems

SCADA systems consist of several crucial components that work harmoniously to provide an integrated control and monitoring solution. Understanding these components is essential to grasp the intricate workings of SCADA technology. Let’s explore them in detail:

- Supervisory Host Computer: Serving as the central command center, the supervisory host computer is responsible for managing and controlling the entire SCADA system. It enables operators to interact with the system, monitor processes, and execute control commands.

- Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs): RTUs and PLCs are hardware devices employed to interface with various equipment and collect real-time data. RTUs are typically used in remote locations to acquire data, while PLCs are employed for localized control and automation tasks.

- Communication Infrastructure: SCADA systems rely on a robust communication infrastructure to facilitate the seamless transfer of data between the supervisory host computer and remote sites. This infrastructure can include technologies such as wired and wireless networks, radio systems, and satellite communication.

- Human-Machine Interface (HMI): The HMI component of SCADA systems enables operators to visualize and interact with the data gathered from remote sites. It provides a user-friendly interface that presents critical information in an intuitive manner, allowing operators to make informed decisions effectively.

Functionality of SCADA Systems

SCADA systems offer a wide array of functionalities, each designed to enhance industrial control and monitoring processes. Here are some key functionalities offered by SCADA technology:

Real-time Data Acquisition:

SCADA systems collect real-time data from diverse sensors and devices, providing a comprehensive view of industrial processes. This data includes parameters such as temperature, pressure, flow rate, and more.

Data Storage and Analysis:

SCADA solutions employ powerful databases to store vast amounts of collected data. This enables historical analysis, trend identification, and facilitates predictive maintenance, leading to increased efficiency and reduced downtime.

Process Visualization:

SCADA’s HMI component offers intuitive visualizations, presenting data in the form of graphs, charts, and diagrams. This enables operators to comprehend complex information quickly, aiding in effective decision-making.

Alarm and Event Management:

It incorporate advanced alarm and event management capabilities. Operators are alerted promptly to critical events or deviations from defined parameters, allowing for swift response and proactive troubleshooting.

Remote Monitoring and Control:

It enables remote monitoring and control of industrial processes, eliminating the need for physical presence at every site. This results in substantial cost savings, increased operational flexibility, and improved safety.

Advantages of SCADA Technology

Implementing SCADA technology offers numerous advantages that contribute to the success of industrial operations. Here are some key benefits:

- Enhanced Operational Efficiency: It optimizes processes by providing real-time insights and enabling rapid response to anomalies. This leads to improved efficiency, reduced waste, and increased overall productivity.

- Improved Safety: Systems monitor critical parameters and promptly alert operators in the event of abnormal conditions. This facilitates proactive safety measures, mitigating potential risks and ensuring a secure working environment.

- Reduced Downtime: Through continuous monitoring and predictive maintenance, It helps identify potential equipment failures before they occur. By addressing issues proactively, businesses can minimize downtime and avoid costly production interruptions.

- Cost Savings: It enables centralized control and remote monitoring, reducing the need for on-site personnel at every location. This results in significant cost savings through streamlined operations and optimized resource allocation.

- Data-Driven Decision Making: With its comprehensive data collection and analysis capabilities, It empowers businesses to make informed decisions based on accurate and up-to-date information. This leads to more effective strategies and improved outcomes.

Conclusion

SCADA technology represents a significant milestone in the evolution of industrial control systems. Its ability to seamlessly monitor and control processes, coupled with its numerous advantages, makes it an indispensable tool for businesses across various sectors. By harnessing the power of SCADA, organizations can optimize efficiency, enhance safety, and unlock new levels of productivity. Embracing this transformative technology paves the way for a future where industry operates at its full potential.

LIKE WHAT YOU’RE READING?

CHECK OUT SOME OF OUR OTHER GREAT CONTENT HERE:

- ADVANTAGES OF STEPPER MOTOR

- WHAT IS A UNIVERSAL MOTOR ?

- WORKING PRINCIPLE OF SYNCHRONOUS MOTOR

- INDUCTION MOTOR: WORKING PRINCIPLE, TYPES & APPLICATION

- HOW ELECTRICAL MOTOR WORKS? – EXPLAINED