STRAIN GAUGE WORKING PRINCIPLE, TYPES & APPLICATIONS

Introduction – Strain Gauge Working Principle:

Strain Gauge is a device which uses change in electrical resistance to measure strain. In this article let’s see about Strain Gauge Working Principle, its types, Applications, Advantages & limitations.

What is a Strain Gauge

A Strain gauge is a device which is used to measure strain (deformation) on an object subjected to forces. A Strain gauge (sometimes referred to as a Strain gage) is a sensor whose resistance varies with applied force. Strain Gauge or Strain Gage was invented in 1938 by Edward E. Simmons and Arthur C. Ruge. Strain can be measured using various types of devices classified depending upon their principle of operation.

Strain gauges are classified into:

- Mechanical type

- Optical type

- Pneumatic type

- Electrical type

- The most commonly used strain gauge is an electrical resistance strain gauge.

- A electrical resistance strain gauge is a passive transducer and also is employed for converting mechanical displacement into a change of resistance.

Characteristics of Strain Gauge:

- A strain gauge should have low resistance temperature co-efficient only.

- Bonding element in a strain gauge must have High insulation resistance

- The sensitivity factor of strain gauge is normally of the order of 1.5 to 2.0

Strain Gauge Working Principle

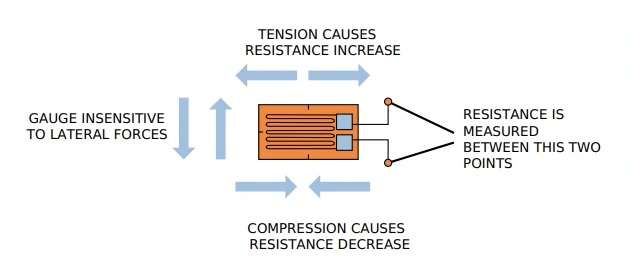

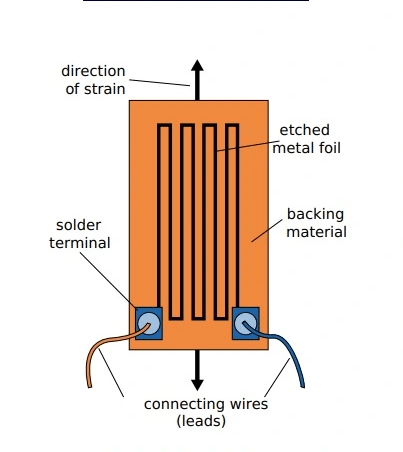

The strain gauge works on the principle that when a metallic wire type gauge is strained (here due to forces on object in contact), the resistance of the wire will be changed due to changes in its length, diameter and resistivity.

Resistance (R) = ρL /A

Where,

R = Resistance

L = Length

A = Cross-Sectional Area

Ρ = Resistivity of the material

This change in resistance will be in proportion with the strain produced which can be easily measured using Wheatstone bridge. Thus Resistance is the important factor in strain gauge working principle.

Strain Gauges Types:

Strain gauges are basically available into four types of:

- Wire wounded strain gauges

- Foil type strain gauge

- Semiconductor strain gauges

- Capacitive strain gauges

Wire wounded strain gauges:

In an electrical resistance strain gauge, the device consists of a thin wire placed on a flexible paper tissue and is attached to a variety of materials to measure the strain of the material. Strain Gauge Working Principle of Wire wound type is that change in resistance is proportional to the strain and is measured using a Wheatstone bridge.

There are two main classes of wire wound strain gauges:

- Bonded strain gauge

- Unbonded strain gauge.

Bonded strain gauge:

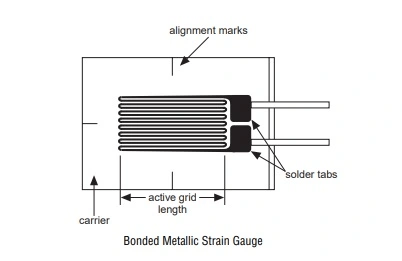

- These gauges are directly bonded (that is pasted) on the surface of the structure under study. Hence they are termed as bonded strain gauges. Along with the construction of strain gauge transducers, a bonded metal wire strain gauge is used for stress analysis.

- A resistance wire strain gauge has a wire of diameter 0.25mm or less.

- Bonded wire strain gauges are used for both stress analysis and also construction of strain gauge transducers.

Unbonded strain gauge:

- It is a type of gauge in which a wire is stretched in an insulating medium in between two points. The insulating medium can be air.

- The wire can be made of alloys such as copper-nickel, chrome nickel, nickel-iron having a diameter of about 0.003 mm.

- Unbonded strain gauges are used in force, pressure and also acceleration measurement.

Limitation of unbonded strain gauges:

The gauge factor for this category of the strain gauge is about 2 to 4 and also capable to withstand a force of 2MN.

Foil Strain Gauge:

This is an extension of the resistance wire strain gauge. The strain is sensed with the help of a metal foil. The metals and alloys used for the foil and wire are nichrome, constantan (Ni + Cu), isoelastic (Ni + Cr + Mo), nickel and platinum.

Semiconductor Strain Gauge:

- Semiconductor strain gauges are used when a very high gauge factor is required. They have a gauge factor 50 times as high as wire strain gauges.

- Strain Gauge Working Principle of semiconductor type is that the resistance of the semiconductor changes with change in applied strain to have a high sensitivity, a high value of gauge factor is desirable.

- A high gauge factor means relatively higher change in resistance, which can be easily measured with a good degree of accuracy.

Limitations of Semiconductor Strain Gauge

- They are very sensitive to changes in temperature.

- Linearity of semiconductor strain gauges is poor.

- They are more expensive.

Capacitive strain gauges:

- Strain Gauge Working Principle of capacitive strain gauge is based on the principle of variation of capacitance with variation of distance between electrodes. The electrodes are flexible metal strips of about 0.1 mm thickness. The strain to be measured is applied to the top plate.

- These change the distance between the curved electrodes resulting in changes of capacitance.

- The strain capacitance relationship in general not linear but variations in dimensions and shape allow gauge characteristics to be chosen so as to match the range of capacitance to be measured with good degree of accuracy

Advantages of Strain Gauges:

Semiconductor Strain Gauge

- Semiconductor strain gauges have a high gauge factor of about + 130. This allows measurement of very small strains, of the order of 0.01 micro

- Hysteresis characteristics of semiconductor strain gauges are excellent, e. less than 0.05%.

- Life in excess of 10 x 106 operations and also a frequency response of 1012 Hz.

- Semiconductor strain gauges can be very small in size, ranging in length from 0.7 to 7.0 mm.

Unbonded strain gauge:

- The range of this gauge is +/- 0.15% strain.

- This gauge has a very high accuracy.

- Limitation of unbonded strain gauges

- It occupies more space.

Drawbacks of Strain gauge

- A strain gauge is capable only of measuring strain in the direction in which gauge is oriented.

- There is no direct way to measure the shear strain or to directly measure the principal strains as directions of principal planes are not generally known.

Strain Gauges Applications

The following are some of the strain gauges applications.

- Bonded wire strain gauges are used for both stress analysis and construction of strain gauge transducers.

- Unbonded strain gauges are used in force, pressure and also acceleration measurement. Unbonded strain gauge is used in places where the gauge is to be detached and used again and again.

- Semiconductor strain gauge are used for measuring very small strains as it have high gauge factor.

Strain Gauge FAQ

What is the principle of strain gauge?

The strain gauge works on the principle that when a metallic wire type gauge is strained (here due to forces on object in contact), the resistance of the wire will be changed due to changes in its length, diameter and resistivity

What are types of strain gauge?

Strain gauges are basically available into four types of:

- Wire wounded strain gauges

- Foil type strain gauge

- Semiconductor strain gauges

- Capacitive strain gauges

What is strain gauge?

A strain gauge is a sensor whose measured electrical resistance varies with changes in strain. Strain Gauge uses change in electrical resistance to measure strain.

LIKE WHAT YOU’RE READING?

CHECK OUT SOME OF OUR OTHER GREAT CONTENT HERE:

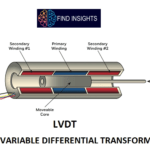

- LVDT- CONSTRUCTION, WORKING PRINCIPLE , APPLICATIONS, ADVANTAGES, AND DISADVANTAGES

- SCR VI CHARACTERISTICS EXPLAINED IN DETAIL

- STEP UP TRANSFORMER: DEFINITION, CONSTRUCTION, WORKING & APPLICATIONS

- LIMITATIONS OF OHM’S LAW

- INDUCTION MOTOR: WORKING PRINCIPLE, TYPES & APPLICATION

- WHAT IS OPERATING SYSTEM AND ITS TYPE

- TYPES OF LIGHTNING ARRESTER

- HOW DOES A CAPACITOR WORKS

- WHAT ARE THE APPLICATIONS OF OP AMP?

- WHAT ARE THE USES OF CAPACITOR

- HOW AN IGBT WORKS?

- VARIOUS USES OF A RESISTOR

- HOW THE MOSFET WORKS?

- POWER FACTOR IMPROVEMENT METHODS

- WORKING PRINCIPLE OF SYNCHRONOUS MOTOR

- SYNCHRONOUS MOTOR STARTING METHOD

- WHY THE SYNCHRONOUS MOTOR IS NOT SELF STARTING

7 Comments